Automation – ICPROD

Production management system

– 15” color touch screen installed on the front panel of the branch with access to all machine controls.

– Auxiliary touch screen installed at the end of the machine that allows the operation of all the main commands. This extra screen allows the machine to continue working even without the main screen.

– Control and adjustment of temperature, speed, width in each field of the machine, input and output, fabric overfeed, output cylinder, etc…

-With our ICPROD program you can store the different parameters and data that you have used in different qualities, with the possibility of recovering them in the future.

The ICPROD system includes:

- Production control

- Configuration of recipes for process control.

- Recipte formula

- Batch control

- Backup of ald batches.

- Possibility of controlling incidents

- Online alarms

- Maintenance: Maintanance greasing management , programmable maintenance control.

- Possibility of access through company network with IC-Remote option, enables online technical assistance

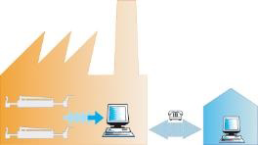

IC-REMOTE

The IC-REMOTE allows the technical assistance through internet without need of travelling.

This configuration can be connected to ICPROD computerized stenters

ICOMATEX delivered all the machines with a copy of the programs on a USB so that the customer has the copy of the program without any additional cost.

ICOSMART 4.0

With the ICOSMART system it is possible to monitor the stenter from a mobile phone or a laptop in real time to check the production, speed, consumption, and other data of the machine by connecting to the cloud.

All the parameters can be seen in real time, at selected periods of time and by production batches. Possibility of connection to the OPC service.

DO YOU WANT TO RECEIVE A QUOTE ADJUSTED TO YOUR NEEDS?